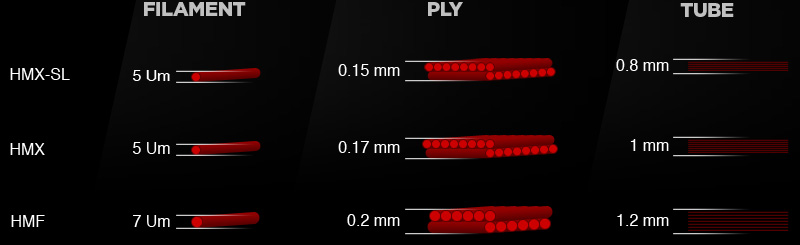

Type of carbon fiber

HMF Carbon fiber

HMF carbon fiber is used to maximize strength and to keep weight low. This material has an optimal blend of stiffness and strength that offers the best riding session. The know-how of SCOTT engineers is utilized in order to create the perfect lay-up with orientation and fiber size. HMF fiber will offer superior strengh compared to the industry standard.

HMF

Tensile Modulus: 125GPa

Tensile Strength 2450MPa

HMX Carbon fiber

SCOTT has improved upon the now conventional high modulus carbon fiber, HMF, used throughout the bicycle industry. HMX is a fiber blend used by SCOTT, and is 20 percent stiffer than its HMF counterpart for the same weight. This unique material allows SCOTT engineers to create incredibly light bikes with excellent riding characteristics. The cost of HMX, however, is three times that of HMF, and is therefore reserved for our high end Premium,Team Issue, and RC frames.

HMX

Tensile Modulus: 154GPa

Tensile Strength: 2950Mpa

HMX-SL

HMX-SL utilizes Nano-technology, which incorporates a carbon nanotube reinforced epoxy resin as well as T1000G carbon fiber. The carbon nanotubes offer an improved strength perpendicular and at off-axis to fiber direction, which allows for a better inter-laminar shear strength. The cohesion between the fibers is improved compared to our industry leading HMX carbon blend offering an unprecedented resistance. T1000G is the world's highest tensile strength fiber. This fiber is traditionally used for aerospace or defense applications. Strategic use of this new material results in a frame that is lightweight without compromise in power transfer.

WHAT IS THE DIFFERENCE

HMX filaments are both stiffer and smaller in diameter than those of HMF carbon. Because of this, an HMX frame can be built of tubes with thinner wall thicknesses to achieve the same stiffness of a corresponding HMF frame.

The final difference between a HMX and HMF frame is mainly the weight. A HMF frame is about 14% heavier than a HMX frame.

HMX-SL is 8.5% lighter on a full frame than HMX

HMX is 14% lighter on a full frame than HMF

| FRAME WEIGHT (Size M) | ||

|---|---|---|

| HMX | ||

| FOIL | 840g | |

| SCALE 900 | 949g | |

| HMX-SL | ||

| ADDICT SL (Frame/Fork) |

710/280g | |

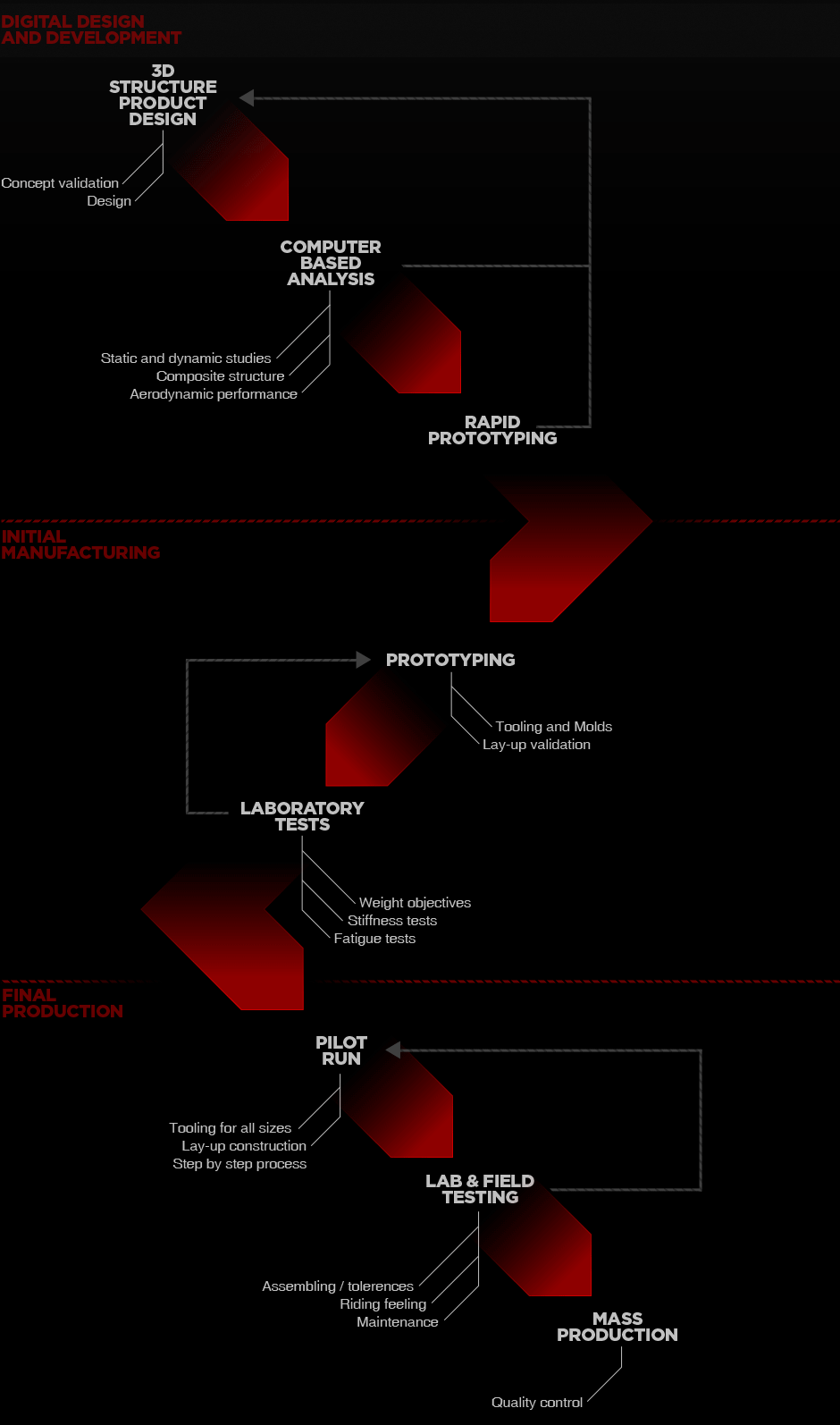

carbon frame production process

This is a story about a carbon fiber SCOTT bicycle. Carbon is the ultimate source material for a high performance bicycle, but carbon is nothing without engineering. Every form, every detail in the layup is a tactical plan with an intended result.

THE PROCESS STEP BY STEP

1. Design & engineering

It begins as a concept where SCOTT's greatest thinkers collaborate on an intended result. SCOTT intends to make the best bicycle in every category. Priority is placed on engineering , with the knowledge that carbon must be optimized in every respect in order to achieve top performance standards and function specific designs. These crude, dark, shiny black fibers, when used correctly, will yield a quality structure that is truly purpose driven and uniquely different in ride quality. This is how a SCOTT get's it's distinct feel.

2. Precision Trimming of the HMX carbon fiber

The key to a Superior layup begins with the engineered shapes that must first be laser cut. Great care is given to utilizing all of the material in a raw sheet. HMX, or High Modulus Xtreme is a unique blend of High Modulus fiber and is very expensive when compared to your 'run of the mill' HMF. The 'bias' of the material, or the direction the fibers, are critical factors considered when the lightweight structure is built. Angles of 0°, 20°, 45° and thicknesses are closely monitored for the consistency of the product, and to maintain the bikes 'feel'. For The Carbon Experts, it means start to finish high quality standards.

3. Preparing the layers

There are over 200 pre-prepared pieces of all sizes that are necessary to construct a single Bicycle frame. Precision over these many repetitions is key to success. Without expert preparation a structure is not 100% managed for quality. SCOTT engineers take great pride in the process of preparation.

4. IMP - Preforming

IMP, or Integrated Molding Process, is a process developed by SCOTT engineers that allows for multiple tubes to be created in a single step while managing the layers completely. When the carbon fiber is fully optimized then less of it can be used resulting in a lighter structure.

Great detail is given to the shapes used in IMP because shapes help manage the loads a frame junction incurs during use. Critical to the process is the pre-tensioning of the raw material, this must be done by hand and this is part of optimizing the material.

5. IMP - Molding process

During the Molding Process the layers are compressed while they cure. This adds integrity to the structure and further optimizes the HMX fibers. This Proprietary Integrated Molding Process is the result of our 20+ year commitment to carbon fiber as a frame material. We invented Carbon Welding, a process widely used throughout the bicycle industry, but we have kept secret the expertise of IMP and we maintain a leadership position in carbon frame manufacturing at present because of IMP.

8. QUALITY CONTROL

SCOTT engineers maintain a high level of Quality Control. Destruction testing is performed at intervals throughout a production run. We know the exact serial number each member of the team has had a hand in producing and which day it was made. Without Quality control no measure of a quality product can be produced.

9. Testing strength & stiffness

Frames are put through rigorous testing during Quality Control evaluations. Fatigue tests are performed in order to gauge the long-term durability of the finished product. The base lines a frame must endure are more than 3x the amount a human being can inflict upon the structure. Every frame we produce is granted Top Performance rating from Engineering for Bicycles, an independent test lab that qualifies all bicycle product for safety and durability.

12. Quality control & shipping

Every SCOTT frame has a serial number which allows quality controllers to track the product in each level of the procedure.

Digital Design

and Development

DIGITAL DESIGN

and Development

SCOTT carbon frames are all designed, engineered and virtually tested prior to opening new molds. Concepts are first validated by our team of designers to ensure that they integrate with the overall SCOTT ethos. Our engineers then build a 3D model of the frame which can then be analyzed by the most advanced FEA and CFD industrial tools, as well as our own, in-house developed, kinematic and composite structure software. These tools allow our engineers to assess a frame's weight and volume, stress distribution, stiffness rating, aerodynamic performance, suspension characteristics with regard to kinematics and spring rates, and fiber ply layup schedules.

INITIAL MANUFACTURING

Once the virtual design and engineering process is completed, the first mold can be opened. SCOTT engineers layup the initial frame themselves. The resulting prototype frames then go directly from the mold to the test lab to assess frame strength and stiffness. The frame will then go through several cycles of layup refinement and testing until all performance targets are met.

FINAL PRODUCTION

Prior to mass production, a pilot run of frames is produced to validate all tooling and layup schedules. These pilot frames are then subjected to further lab testing, before being ridden in real world conditions. It is at this point that our professional teams and riders enter the equation, pushing the bikes to their limits and providing valuable feedback.

TEST & RESULTS

-

Weight

SCOTT has built a reputation for creating lightweight, carbon fiber bikes, but frame strength is of equal priority to weight when considering a bike. SCOTT bikes would not deserve the praise they receive if it were not for their superior balance of light weight, stiffness, and performance, and we set this as a goal for our entire bike line.

FIRST SCALE

NEW SCALE

IMP Process

Integrated Molding Process, or IMP, is a method developed by SCOTT engineers where complex frame tubes and joints can be created in a single step. This process not only eliminates a considerable amount of material used in more traditional tube-to-tube construction, it also gives engineers freedom to introduce more optimized structures and to fully control carbon layup and frame performance. IMP therefore yields a lighter, more durable and better performing bicycle.

SCOTT Results

-

Stiffness

In general, the stiffer the frame, the quicker it will translate a rider's pedaling forces into acceleration. We therefore focus on maximizing torsional and rear triangle stiffness without adding any additional weight to the overall structure.

Testing Process

SCOTT engineers assess several different frame criteria in order to improve overall bike performance. To determine bottom bracket stiffness, weights are applied to a dummy crank arm and chain, oriented at the peak pedal force input position and resultant deflection measured.

To measure the stiffness of a frame along its whole length, the frame is fixed at the rear dropouts and a torsional load is applied to a bar extending from the headtube. To measure frame comfort, the frame is fixed at the rear dropouts, a load is applied to the top of the seatpost and the resultant vertical deflection measured.

SCOTT Results

Stiffness is not the only measure when it comes to evaluating bike performance. Each SCOTT bike is specifically designed and engineered to match the end users' needs with regards to comfort, handling, aerodynamics, in addition to stiffness. Every bike in our line-up has a separate purpose and attribute set.

-

Performance Standard

EFBe is a leading independent laboratory which tests bike frames and components for safety and reliability. SCOTT submits its frames to EFBe for third party testing as a final quality assurance check and to ensure that they all meet the most rigorous demands. EFBe's test ratings and seal of approval serve as validation that when a consumer buys a SCOTT bike, he or she is buying the best bike on the market.

Testing Process

SCOTT frames undergo an accelerated series of fatigue tests in order to simulate the types of stresses they will incur during use. These are done by repeatedly applying precisely defined forces. A frame passes only when it is able to withstand 100,000 cycles of each test without showing signs of damage. Under even the most extreme use, a human could not match the demands the testing applies to the frames.

There are three primary test segments undertaken to measure frame strength and durability. The first is an 'out-of-saddle' test designed to simulate the forces powerful cyclists exert on the bottom bracket area during pedaling. The second is a 'rider load' simulation to measure the vertical load a frame can withstand, and the third is a 'jump' test to replicate the loads to a frame must endure as a result of heavy braking, striking an obstacle, or jumping.

SCOTT Results

EFBe offers different certification levels, Top Performance, High Performance, and Standard Performance, based on their independently developed testing protocols. The Top Performance level is awarded only to those frames which can successfully withstand 100,000 cycles of the highest test loads without developing any cracks or fractures.

All SCOTT frames, whether carbon or alloy, achieve EFBe's Top Performance rating. It is a testament to the Integrated Molding Process that SCOTT carbon fiber frames can not only be made extremely lightweight, but that they can also achieve the highest standard for strength and integrity.

SCOTT Scale 700 Carbon

SCOTT Scale 900 RC

SCOTT Scale 600 Contessa

Merida O.Nine

SCOTT Addict CX

Bulls Black Adder

Cannodale Flash

Specialized S-Works Fact Carbon

Trek Elite 9.9

CARBON BIKES

ROAD BIKE SERIES

ADDICT

The SCOTT Addict SL comes equipped with a new Superlight HMX-SL Carbon Fiber frame and fork making up a frameset that weighs in at just 1kg- our lightest bike available. Throw in a compilation of high-end Carbon components, and the Addict SL becomes a remarkable and precise feat of SCOTT engineering.

SOLACE

The SCOTT Solace 10 was designed to provide you with a perfect balance of comfort and performance on the roads. Its HMF Carbon Fiber frame was designed with two zones, a Power Zone and a Comfort Zone, in order to result in a stiff and responsive bike that will also keep you comfortable all day long- regardless of frame size. Find your Solace.

FOIL

The FOIL represents the perfect balance of Lightweight, Aerodynamics, and Stiffness, resulting in the most advanced Racing bike available. The FOIL, your next bike.

CR1

The CR1 offers the perfect balance of performance and comfort. Designed to save the rider from shocks and vibrations created by rough roads, the CR1 is the ideal choice for the enthusiast or racer who wants to enjoy long rides but doesn't want to feel beat up at the end of the day.

PLASMA

The Plasma's range incorporates SCOTT Aerodynamic Science and a unique carbon molding expertise to create no compromise machines. Plasmas are designed to help the rider minimize aerodynamic drag; they are ideally suited to Triathlons, Time Trials, and should be your choice in any race against the clock when the wind is your biggest enemy.

MOUNTAIN BIKE SERIES

SCALE

The Scale is designed for maximum efficiency and minimal weight. This bike has modest amounts of front suspension and is the lightest in its class.

SPARK

The Spark is suitable for everyday riders as well as for endurance racers. This bike has more suspension travel than the Scale but is still very weight conscious.

GENIUS

The Genius is a full suspension bike designed to handle any trail, any time. It's the ultimate trail bike suitable for marathons and multi-day stage races.

GENIUS LT

The Genius LT is the ultimate Enduro machine. Its added suspension travel makes it ideal for all technical descents and its pedaling efficiency will get you up any mountain.